Nanojet Principles - Aerosol Based Print Technology

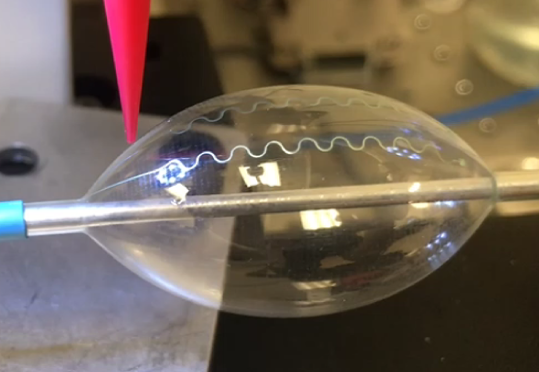

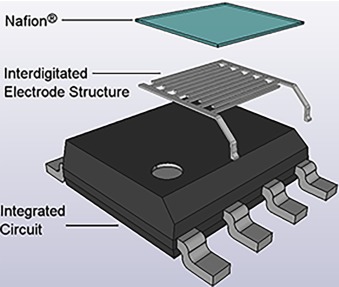

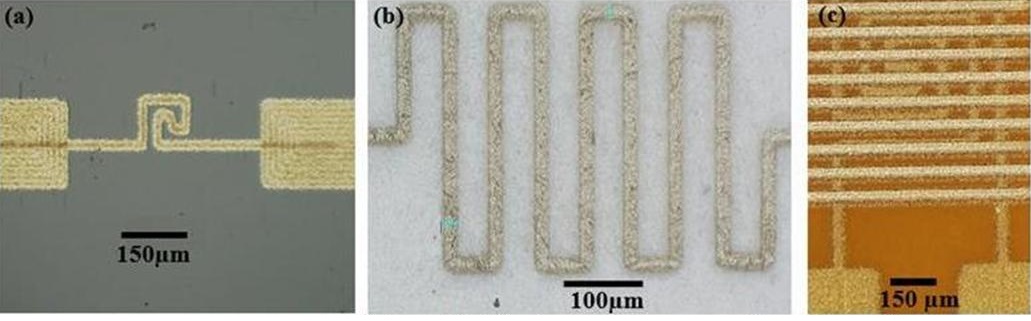

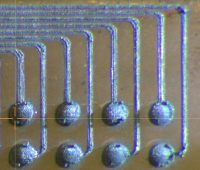

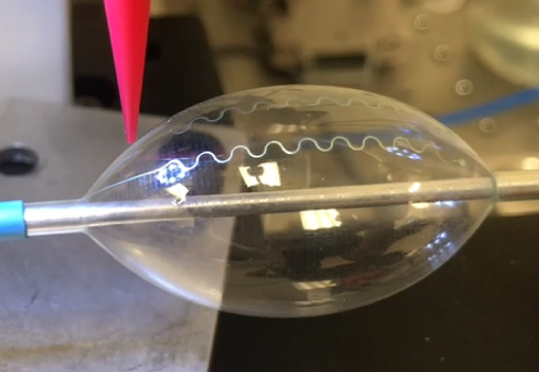

IDS Nanojet Uses Aerosol based printing technology which enables 3D printed electronics. Electronic components such as resistors, capacitors, antennas, sensors, and thin film transistors have all been printed with IDS Nanojet. The performance parameters of printed components, for example the ohm value of a resistor, can be controlled through printing parameters. Components can also be printed onto 3 dimensional surfaces eliminating the need for a separate substrate thereby reducing the size, thickness and weight of the end product. For example, Aerosol Based Print Technology is used to print antennas and sensors that conform to the shape of the underlying substrate such as a cell phone case.

The IDS Nanojet supports printing on a wide variety of substrates including plastics, ceramics and metallic structures. Commercially available materials, such as nano-particle inks, have been optimized for the Aerosol process to allow printing (and subsequent ink sintering) onto plastic substrates with low heat deflection temperatures.

Also, Nanojet can print conformal interconnects on 3D surfaces eliminating the need for wire bonding – for example printing electrical connections on 3D stacked die or for LED chip fabrication.

Process Specifications

Inks

Conductive and Insulating

Working Distance

1 – 10 mm

Line Widths

20 – 200 μm (Single Pass)

Print Speed

5 – 50 mm/s

Line Thickness

0.1 μm – 4 μm

Ink Utilization

100%

Advantages

Ease of Use

High reliability

Quick material changeover

Low maintenance

Large Working Distance

2mm-10mm Nozzle to substrate distance

Simplified principal on planar surfaces.

Production-Oriented Solution

Mean-time between assist > 8 hours

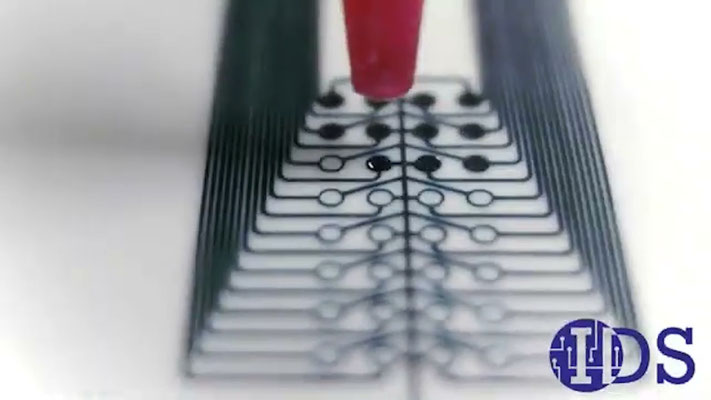

Well-defined printed edges

Line width and resistance < 5% variation

Minimal Overspray and Satellite Deposition

High definition traces

High density interconnects

Aerodynamic Focusing

The NanoJet Printhead uses aerodynamic focusing as a sheathed, aerosol-laden stream traveling through a cylindrical channel is passed through an orifice, undergoing one contraction upstream of the orifice and one subsequent and immediate expansion downstream of the orifice. A contraction of the aerosol stream is produced as the flow approaches and passes through the orifice. The gas then undergoes an expansion as the flow propagates downstream into a wider cross-sectional area. Flow through the orifice forces particles towards the flow axis, so that the aerosol stream is narrowed and collimated.

Hydrodynamic Focusing

Hydrodynamic focusing using a sheath gas is generally accomplished by propagating an annular sheath/aerosol-laden inner flow through a continuously converging nozzle using differing sheath and aerosol gas flow rates. The degree of focusing is proportional to the ratio of the gas flow rates. As the sheath gas flow is increased, the volume available for the aerosol-laden inner flow is decreased so that the aerosol stream is stretched to a reduced diameter as the combined flow passes through the nozzle orifice.

Single & Dual Material configuration

8-Hour Print Stability

The NanoJet process and apparatus are designed to provide multiple hours of stable, unassisted operation. NanoJet stability has been characterized in studies of line width as a function of time. In a typical stability study, printing is started and maintained for several hours, and linear traces of silver nanoparticle ink are deposited on a glass substrate at five or ten minute intervals.

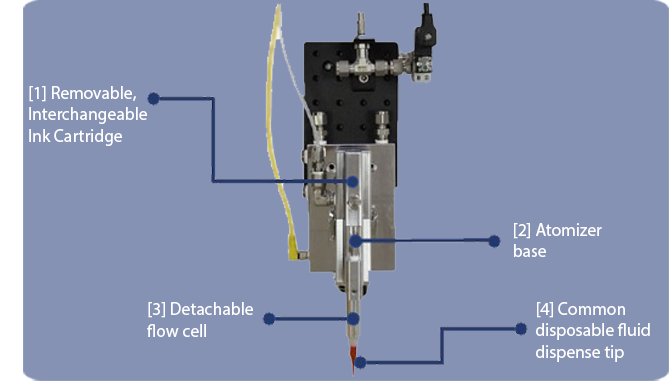

Modular Design

The NanoJet Print Module uses a modular design with removable ink cartridges that can be quickly changed to print different inks.

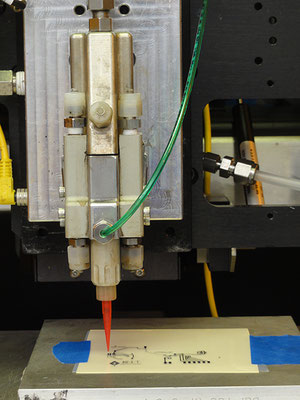

IDS offers free-standing and desktop solutions for printed electronics applications or an integrable subsystem that can be retrofitted to existing motion control platforms.

NanoJet Desktop

Complete printing solution

Desktop configuration

Single and dual material configurations

COMPONENTS

Print Module

3-Axis Motion Control Module

Process Control Module

Part Alignment Camera

Process Vision Camera

Nanojet FS System

Complete printing solution

Standalone configuration

Available in single and dual-material configurations

COMPONENTS

Print Module

3-Axis Motion Control Module

Process Control Module

Part Alignment Camera

Process Vision Camera

Windows 10 Computer

Nanojet Subsystem

The NanoJet Subsystem is an economical print solution designed to be retrofitted to a pre-existing motion control module. The Subsystem uses the same Print Module as the (Full) FS System and Desktop systems and has the same printing capability.

Economical solution

Easily fitted to suitable motion systems

Single and dual-material configurations

COMPONENTS

Print Module

Process Control Module

Process Video's

Contact Us:

Ambition Technologies

17-FF, Pocket 2, Sector 24

Rohini, New Delhi - 110085 India

Phone:

# 9810400671 / Pranay@ambitec.org

# 9911223020 / Rahul@ambitec.org

Email: sales@ambitec.org